Prodigy Dispenser

Overview

The Camalot Prodigy dispensing machine uses cutting-edge technology to achieve faster processing, greater accuracy, and improved yields. The machine's X Y gantry system, linear drive technology, refined motion control, and sturdy frame design provide excellent performance and reliability.

With the advanced linear-drive architecture and stable frame, the Prodigy can achieve high precision at high speeds, resulting in consistently better yields with a +/- 35µ 3 Sigma dot placement accuracy at full speed.

The machine also has an innovative board staging option that can double or even triple the dispense area in the X direction, allowing for processing of products up to 900mm in size.

Both contact and non-contact heating options, including heated lift chucks, ensure that dispense materials are maintained at a controlled temperature for consistent, repeatable material flow rates for underfill and encapsulation.

The Prodigy's features can be easily upgraded in the field, due to its "plug and play" compatibility and simplicity. This includes upgrades to heat, pumps, weight scale, 2nd Z-axis, and even the conveyor system.

Featured Technology and Benefits

Patented technology that enables reduced wet-out areas, improved capillary flow for underfill and access for dispensing on side walls or around tall components.

PCB designs are ever more challenging for dispensing with increased component densities, reduced materials keep out zones, and a broad mix of component heights. The Prodigy's advanced Tilt and Rotate option solves all these challenges and more with its patented design and operation.

Key Features:

- DC servo control for both axes

- 0.01 degree resolution

- Up to +/- 45 degrees of Tilt and +/- 90 degrees of rotation

- Both axes programmable in sub-degree increments

- Automatic setup and calibration

- Extended fluidics and nozzles provide additional clearance for “hard to reach” applications

Click here to watch the Tilt and Rotate video

The proprietary design of Dynamic Dual Head (DDH) provides the only fast and fully accurate solution for dual head simultaneous dispensing. The DDH option uses a unique and patented mini XY drive system on a second Z-Axis to correct “real-time” and allow synchronous dispensing of both pumps regardless of part to part rotation. This technique guarantees increased productivity whilst maintaining yields through unsurpassed accuracy.

Key Features

- Independent, real time adjustment for both dispense pumps

- Dispense productivity increased by up to 100%

- No yield loss due to second head inaccuracy

- Compatible with all dispense pumps

- Automatic setup and calibration

Click here to watch the DDH video

NuJet eliminates use of a needle and incorporates a contact jetting technique to displace the dispense material. Controlling the piston with a pneumatic actuator and closed-loop software achieves a high degree of accuracy and repeatability for consistent process results.

Features

- Speeds up to 300 Hz

- Auto-tune for closed-loop calibration

- Setup time reduced by 20%

- Dot sizes < 300 microns

- Extended maintenance frequency

Click here to watch NuJet video

Offering high speed - Up to 600 Hz, and ultra-fine resolution, with dot sizes 300 microns, this patent pending pump features state-of-the-art motion control technology, simple maintenance, quick changeover, and a low cost of ownership.

Patented, closed-loop monitoring of the PCB/substrate temperature ensures dispenser process stability and yield improvements for underfill applications.

Features

- Closed loop control of the product temperature through the entire process.

- Compact, miniature design has no impact to gantry XY travel.

- GUI displays in “real time” the product temperature in each zone

- All settings are stored in the process program and tied directly to the product

- OpenApps feature allows the data to be transferred into factory MES systems

Proprietary syringe cooling technology that increases the “pot-life” of underfill materials by maintaining the syringe at controlled temperature within the heated machine environment. This provides reduced material waste, less downtime and increased process stability.

Key Features

- Extends underfill material life

- Proprietary cooling technology

- Fully integrated software controls

- Monitors material level in the syringe

- Reduced overall running costs

- Compatible with Camalot pump technology

A patented closed-loop weighing process measures dispense patterns and automatically compensates for material viscosity for maximum accuracy.

Camalot offer 2 types of Auger pump both controlled with a precise servo drive system. The 635SD series are typically used for finer feature dots and lines of high viscosity material. The 680SD pumps delivers high flow rates and also incorporate a patented positive shutoff that eliminates dripping of lower viscosity materials. For highly abrasive materials both pump systems offer more wear resistant carbide auger screws.

SmartStream is a unique patented non-contact dispense method designed and manufactured by Camalot. A controlled stream of material is dispensed using positive displacement with a piston, which does not contact seat or nozzle. SmartStream dispenses a column of material with each cycle instead of a single sphere.

Independent Dual Head configurability allows dispensing of different materials within one process. Both Z-axes are independently controlled, facilitating both high positional accuracy and fast axis movement.

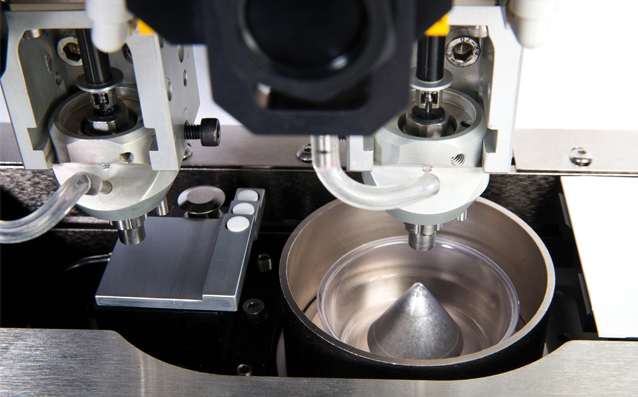

A vacuum-based cleaning station ensures cleanliness of needle/nozzle. A detector is used to verify needle straightness and presence, compatible with 12–32 gauge needles.

The Prodigy features automatic vision for both fiducial alignment and manual teaching of programs. Fiducial images are taught and saved to an onboard library; in addition, it works as an image recognition system so that any unique feature can be used for alignment. Camalot’s edge detection vision alignment is the fastest and most accurate positioning method available. A one-snap operation finds all four edges of die up to 25mm square, and automatically adjusts needle path for variations in X,Y, and theta placement, die width, and edge parallelism.

Easy to learn and use, ITW EAE’s Benchmark software is powerful yet intuitive, and offers enhanced functionality and features such as a flip chip calculator for underfill. It outputs accurate volume and weight details by allowing precise weight data to be entered into the program, reducing setup time and scrapped parts.